Quality & Manufacturing

Our Commitment to Quality

At EquipmentGroup.com, quality is not just a standard; it's the foundation of everything we do. From the initial design phase to the final product inspection, every step is meticulously controlled to ensure our equipment meets and exceeds the highest industry benchmarks.

We employ rigorous testing protocols, utilize advanced analytical tools, and adhere to a zero-tolerance policy for defects. Our dedicated quality assurance team works tirelessly to guarantee that every piece of equipment leaving our facility is robust, reliable, and ready for the most demanding applications.

Advanced Manufacturing Processes

Our state-of-the-art manufacturing facilities are equipped with the latest technology, including automated CNC machining, robotic welding, and precision assembly lines. This allows us to achieve unparalleled accuracy, efficiency, and consistency in production.

We continuously invest in research and development to integrate innovative techniques and materials, ensuring our manufacturing processes are at the forefront of the industry. This commitment to innovation translates into superior products for our clients.

Certifications and Standards Support

ISO 9001 Process Alignment

We align our processes to support our customers in meeting international ISO 9001 standards for quality management systems.

CE Mark Support

Our products are designed to facilitate our customers' compliance with European safety, health, and environmental protection requirements (CE Mark).

ASTM Standard Integration

We integrate American Society for Testing and Materials (ASTM) standards into our manufacturing to support client-specific requirements.

Explore Our Solutions

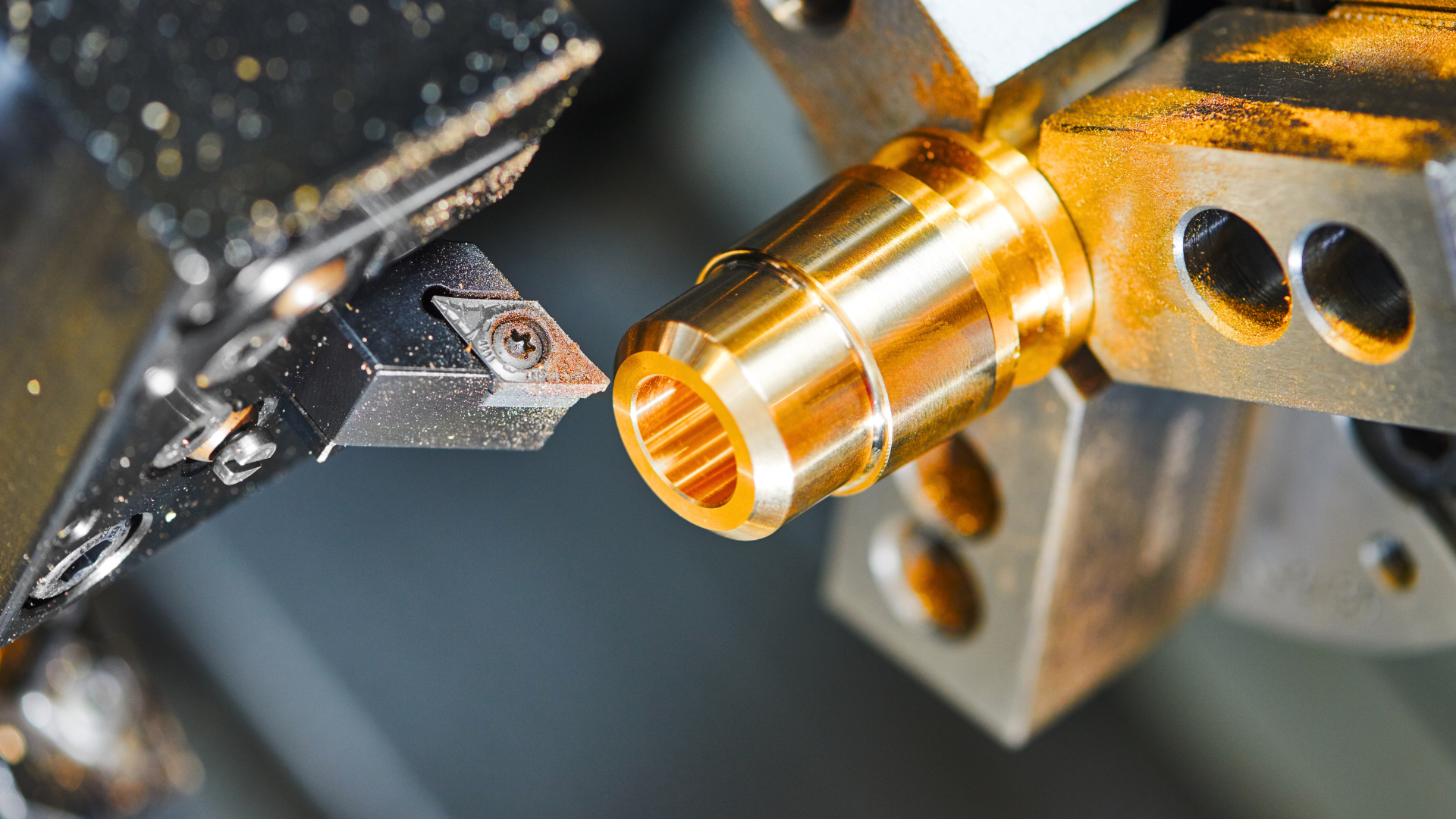

Cutting-Edge Production Methods

Our facilities leverage the latest in manufacturing technology to achieve superior efficiency and product quality.

- CNC Machining: Precision computer-controlled machining for complex parts.

- Robotic Welding: Automated welding for consistent, high-strength joins.

- Automated Assembly: Streamlined assembly processes for speed and accuracy.

- Lean Manufacturing: Principles applied to minimize waste and maximize value.

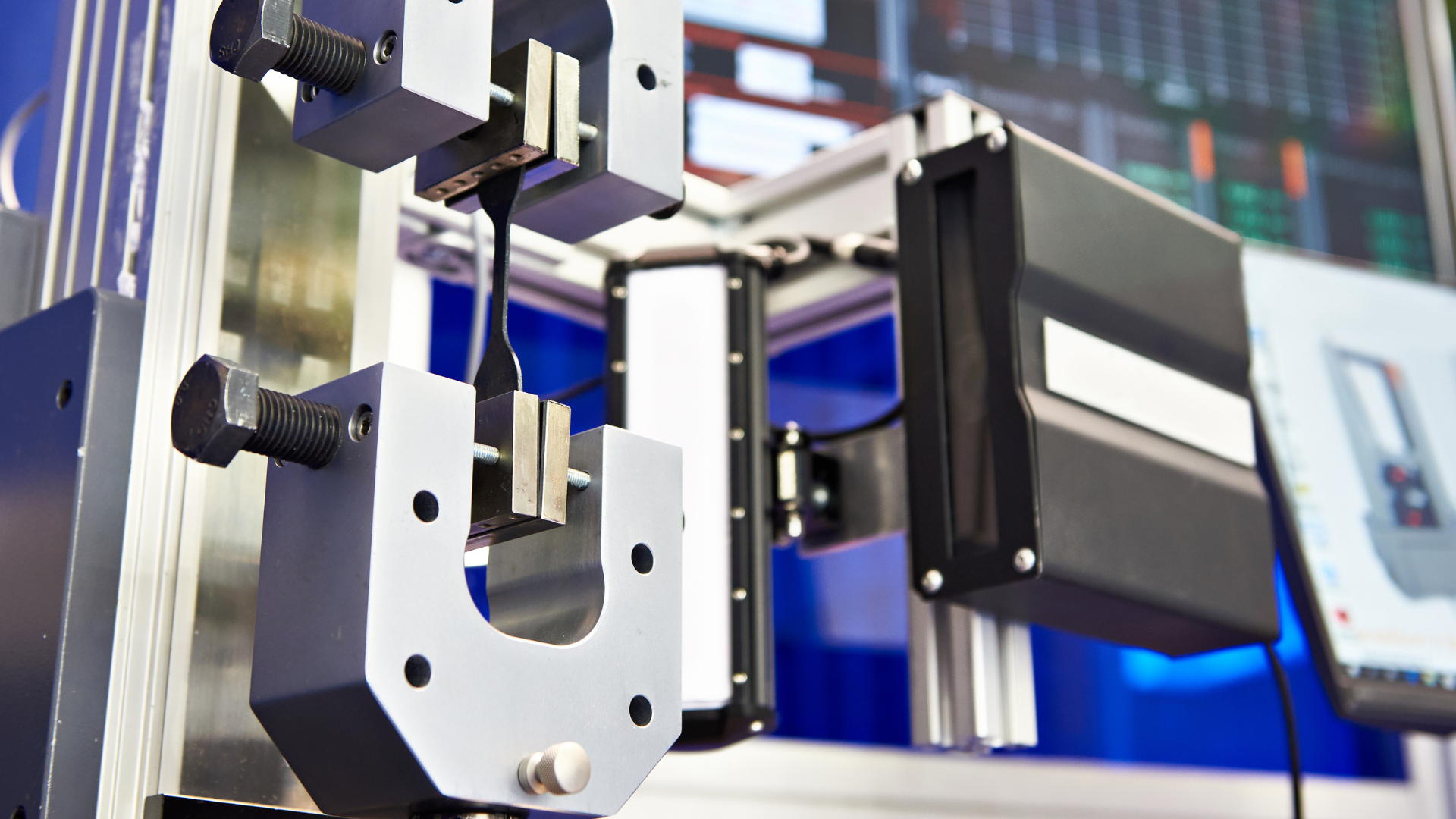

Superior Materials & Validation

We select only the highest-grade materials and subject them to stringent testing to ensure durability and performance.

- Certified Alloys: Sourcing materials with verified metallurgical properties.

- Material Hardness Testing: Ensuring optimal strength and wear resistance.

- Corrosion Resistance: Testing materials for performance in harsh environments.

- Fatigue Testing: Assessing material resilience under cyclic loading.

Supporting Your Compliance Needs

We actively support our clients in achieving and maintaining compliance with various industry standards and certifications by integrating these requirements into our product design and manufacturing processes.

- ISO 9001 Alignment: Our quality management systems are designed to align with ISO 9001 principles, facilitating your certification efforts.

- CE Mark Facilitation: We ensure our products meet the essential requirements for CE marking, assisting your market entry into Europe.

- ASTM Standard Integration: Our equipment is manufactured with adherence to relevant ASTM standards, supporting your project specifications.

- API Specification Support: For oil and gas applications, our products are built to support compliance with American Petroleum Institute (API) specifications.

Our Commitment Beyond Manufacturing

Expert Consultation

Our team of engineers and specialists provides in-depth consultation to help you choose the right equipment for your specific needs.

Custom Solutions

We offer custom manufacturing and modifications to ensure our equipment perfectly integrates with your existing operations.

After-Sales Support

Our commitment extends beyond the sale with comprehensive support, maintenance, and spare parts availability.

Training & Education

We provide training programs to ensure your team can operate and maintain our equipment safely and efficiently.

Discover the Equipment Group International Difference

Learn more about our quality assurance and manufacturing capabilities, or discuss your specific equipment needs with our experts.